Prepare for Production

At the end of an outage cycle, you should be confident that your control valves will function throughout your next production cycle. Industrial Valve Services offers control valve repair along with diagnostic services that calculate mean time to failure (MTF).

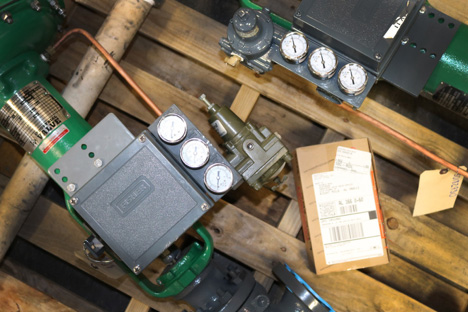

Brands we service include Masoneilan, Fisher, Samson, Copes Vulcan, and Valtek. Our technicians are also skilled in repairing and maintaining Masoneilan SVI and Fisher FIELDVUE positioners. (Looking for a brand name not listed here? Call us – we have a large inventory of control valves and parts from numerous manufacturers).

Our Process

Whether we’re troubleshooting a malfunction or evaluating MTF, we use BenchMark Control Valve Diagnostics. With this efficient and reliable tool, most tests can be completed in 15 to 30 minutes. We provide test/repair reports at no additional cost. Full-page graphics can be resized or customized and are immediately available for print, preview, or export.

Predictive Maintenance

Control valve assemblies may be composed of actuators, internal trim parts, transducers, snubbers, limit switches, and more. Any fault in any of those components could lead to unplanned downtime and emergency repairs. That’s why predictive maintenance is so important.

A good predictive maintenance plan also ensures your processes are compliant with applicable standards from oversight organizations, such as the American Petroleum Institute or Fluid Controls Institute.

Investing in the Future

Over time, your production processes may evolve, and your existing valve assemblies may be insufficient – or incompatible with new components. We can help you upgrade features or choose replacement valves, and we offer removal and installation services. Should you ever need an emergency repair, our technicians are on-call 24 hours a day, 365 days a year.

Make the most of your outage cycle – contact us now to schedule maintenance or repair.