Safety Relief Valve Repair

Need a new seal for your Farris PRV? A fastener for your Crosby safety valve? We carry parts for a variety of brands, and our VR-certified technicians are available 24 hours a day, 365 days a year. Our field service team uses state-of-the-art diagnostic tools to conduct in-line testing of pressure relief and safety valves.

Manual Valve Repair

We can repair angle, ball, check, gate, globe, knife, and plug valves of all sizes (from 1/4” to 108”). We repair low-pressure (150, 300, and 600-lb.) bolted bonnet valves, as well as 900, 1,500, 2,500, and 4,500-lb. pressure seal valves. With a vast inventory of name-brand parts, surplus valves, and discontinued components, we can find the right parts to maintain and repair any valve.

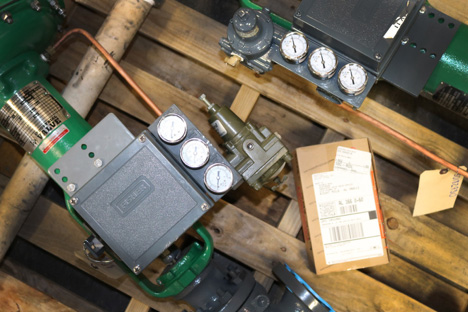

Control Valve Repair

We can troubleshoot, repair, remove, or install any control valve in your workflow. We service many brands, including Masoneilan, Fisher, Samson, Copes Vulcan, and Valtek. Our technicians are also skilled in repairing and maintaining Masoneilan SVI and Fisher FIELDVUE positioners. When a control valve fails during your production cycle, we can help you minimize downtime with our repair-by-exchange program.

Actuator Repair

It requires a high degree of precision and training. So why should you choose Industrial Valve? IVS combines a commitment to customer service, training, knowledgeable staff and an exceptionally large stock of actuators and parts to be the best choice for your actuation needs.

Repair by Exchange

We’re not the only company that offers repair by exchange, but we believe our level of service is unmatched in this industry. When you partner with Industrial Valve Services, you won’t have to lose man-hours removing or installing your valve. Our team of VR-certified technicians handles valve removal, transportation, installation, and testing – and we’re available 24 hours a day, 365 days a year.

Field Services: Repair & Machining

Industrial Valve’s field services team has many years of combined technical experience. They manage personnel, tooling, testing, and customer service to deliver quality services in the field. Our field team can also perform routine and ongoing maintenance and conduct pass/fail testing during scheduled outages. Keep your operations running smoothly with IVS.

Metallurgical Testing

Using a state-of-the-art Niton portable alloy analyzer, we can inspect metals and produce the documentation you need to prove regulatory compliance, or to reassure your partners in the supply chain. Our positive materials identification experts can help you avoid problems like weak welds, stress corrosion cracking, and dangerous alloy interactions.

Particle-Free Cleaning

Industrial Valve has a state-of-the-art particle-free cleaning facility designed for cleaning to the most stringent of standards. We also have a fully-equipped cleaning trailer that can travel to your facility. It has the same capabilities offered in our stationary cleanroom facility, from process separation to trained and knowledgeable technicians.

Minimize downtime – call Industrial Valve for valve sales, field service, repair, or replacement!

Fill out the form below

Call IVS Today!

Contact Us Now

Industrial Valve is ready to answer your questions about field service, repairs, and sales.